Table Of Content

To create a better thread, round the crest and roots in the design process — sharp edges tend to concentrate stress. To avoid broken 'arms and legs,' add triangle supports or 'ribs' around protruding pieces to support the base. Ribs strengthen fragile protruding features by supporting perpendicular angles. Without additional support around their bases, these structures are more likely to snap off. If you're printing a piece that has a protruding feature jutting out from the base, you'll run the risk of that piece breaking, even during the printing process. This technique minimizes the need to use supports, but only when you orient the part facing upwards, which limits object rotation.

Consider File and Slicer Compatibility

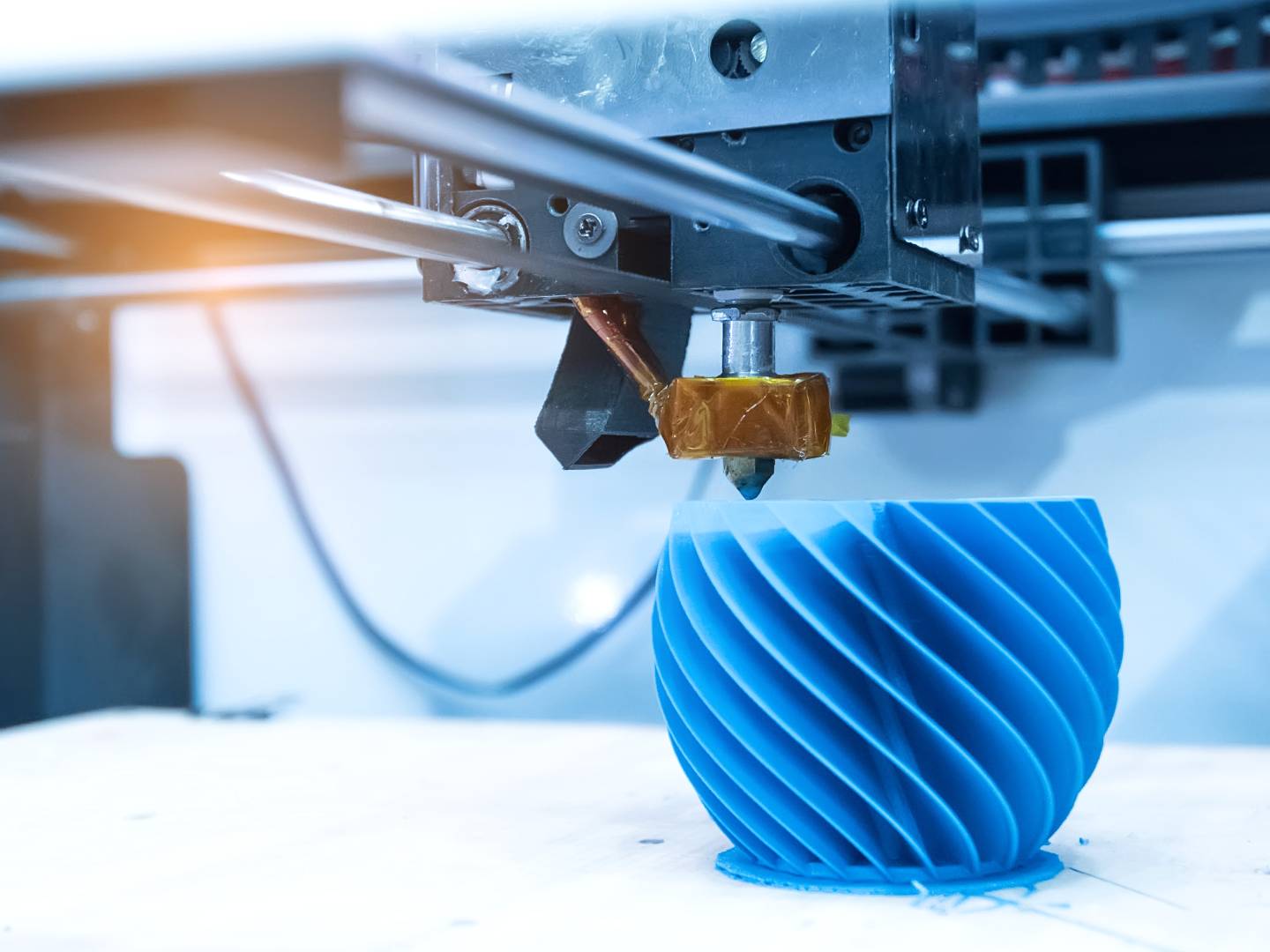

When you're exporting a file for 3D printing, always use the highest setting STL file. STL files are a list of triangles, and cannot store separate bodies. Here's what that looks like on Lulzbot's free CURA slicer interface. An overhang that stretches out beyond 45 degrees requires you to include supports so that your build doesn't tip or lose form. There's nothing wrong with supports, but unless you print with a soluble material using a dual extrusion printer head, they'll probably leave a mark when you take them off.

Easy print in place Big Box

Additionally, you can draw a 2D base for your eventual 3D model using their Sketcher Workbench tool, and use that blueprint to then build up your 3D design. Heavily adopted in architecture, rapid prototyping for product design, and especially in mechanical engineering, FreeCAD has everything you need to create great prototypes, vehicle models and other fun projects. If you notice that some of the layers are not level or sticking together, you may have drafts of cool air moving through your print job. This can be fixed by moving your printer to a location away from any vents, doors, or windows. Alternatively, many 3D printing enthusiasts choose to build an enclosure around their printer to prevent any air from moving over their parts while they're being printed. Ideally, you will want self-tapping screws that are around 3/8 inches in length.

How Does CAD Software Work With 3D Printing?

To anticipate and prevent these challenges, keep each guide item in mind during your design process. The more beginner-friendly options will serve you well if you’re simply testing the waters or only have a basic print in mind. Schools and educators favor TinkerCAD across the globe for its effortless ease of use, intuitive design, and colorful interface.

U.S. Open Tennis Racket Design Brought to Life with Metal 3D Printing - 3DPrint.com

U.S. Open Tennis Racket Design Brought to Life with Metal 3D Printing.

Posted: Thu, 18 Jan 2024 08:00:00 GMT [source]

Find, Share and Sell 3D Print Files

The learning curve is not too steep, and Rhino themselves include a wide variety of tutorials to most of the complex tools available. Overall, it’s another good 3D printing software option for designing printable 3D models. The second section of this list of the best 3D printing software tools focuses on programs that help you to execute a 3D print. Slicers are the easiest way to go from a 3D model to a printed part because they take a CAD model, slice it into layers and turn the model into G-code.

How to design for 3D printing

The software we'll be using today is the free, web-based 3D modeling platform Onshape. If you are still hesitating to share your models on Cults, feel free to read this article Why publish my designs on Cults? Cults3D is an independent, self-financed site that is not accountable to any investor or brand. Almost all of the site's revenues are paid back to the platform's makers. The content published on the site serves only the interests of its authors and not those of 3D printer brands who also wish to control the 3D modeling market. Even though it isn’t the most user-friendly software, it hosts a large set of features while running smoothly.

Getting Started with 3D Printing Using Tinkercad

Increasing the area of the surface in contact with the bed will decrease the likelihood of the warpage. Our monthly UltiMaker Cura newsletter keeps you informed about latest releases, plus free 3D printing tips and resources – all straight to your inbox. Now we bring this to the professional 3D printing market with the UltiMaker Marketplace. Classic Paint has been reimagined, with an updated look and feel and a ton of new brushes and tools. The rest of the process is extremely simple, really, so I’d mainly worry about learning 3D design.

Another feature that new users might find useful is the pull feature that allows users to create 3D models from only a surface. It is feature-rich for a free software and quite beginner-friendly. Blender is actually a free 3D modeling software which was originally for 3D animation and rendering using polygonal modeling techniques. Despite its origins as a software for artists, it is considered quite accessible. One of the software’s interesting features is the photorealistic rendering option. This gives the models an air of realism that few free software can achieve.

3D printing is done layer by layer from the ground up and the printer can print at an angle without any issues or loss in printing quality as long as that overhang angle isn’t too steep. Imagine printing a round sphere where the bottom is rounded as well. Fusion 360 (Link to Review) is probably the best-known CAD currently being used by 3D printing enthusiasts since it’s extremely powerful and capable of creating every 3D model imaginable. The Army Corps of Engineers provided most of the funding for the new printer, which cost several million dollars, said Dannel Malloy, chancellor of the University of Maine System. It was built by the university in collaboration with Ingersoll Machine Tools Inc. for construction of the printer and Somatex for the supporting structure, officials said.

World’s largest 3D-printer that could create ‘neighborhood’ of stylish tiny homes with ultramodern inter... - The US Sun

World’s largest 3D-printer that could create ‘neighborhood’ of stylish tiny homes with ultramodern inter....

Posted: Wed, 24 Apr 2024 02:00:00 GMT [source]

The molten plastic that comes out of the extruder also has a habit of "melting" a bit around the edges, which can cause holes to shrink. In addition, using self-tapping screws forces some of the material to move out of the way, which can cause stress and fractures in the plastic. As a result, we'll need to oversize the drill holes by 0.01 to 0.02 inches.

Brims create suction and hold down the edges of your part by helping it stick to the bed. Assess your printing material and the height of your wall to determine whether it needs additional support. A wall that's already bolstered by ribs or webs (we'll get to those soon) can be thinner than a freestanding wall. Overhangs that stretch effortlessly out into the ether on your iPad screen may come crashing down into a melted plastic mess from your printer. Perfectly concentric holes in your model may better resemble a deflated basketball in the real world.

If you don’t mind honing your knowledge and skill, then advanced programs like Fusion360 and Blender are good options. The real draw is that DesignSpark achieves this without the complexity of most pro-geared CAD programs thanks to intuitive design tools, support for common file formats, and user-friendly interface. Though not specifically geared to 3D printing, FreeCAD does ease the process of preparing models for printing with file export options that include OBJ and STL.

No comments:

Post a Comment